AI-Powered Robotics Perfecting Electronics Quality

In the electronics industry, precision and cleanliness are not optional—they are essential. Maintaining strict quality standards is critical for ensuring that every electronic component performs reliably. Advanced robotics assembly lines, clean room environments, and state-of-the-art automation work together to deliver quality you can trust. At IGNOMAGINE, we leverage EnMac’s AI-powered robotics technology to help manufacturers achieve unparalleled precision and efficiency in their production processes.

Quality You Can Trust

In this high-stakes industry, even a minor mistake can impact product performance. By implementing modern automation and rigorous quality control, manufacturers can ensure every process meets strict industry standards. EnMac’s innovative solutions provide the tools needed to maintain these standards, optimizing both quality and production efficiency.

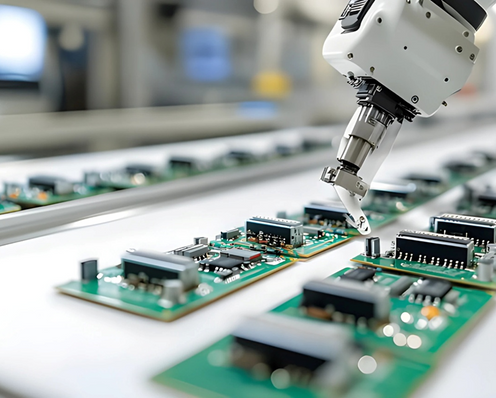

PCB Assembly

Printed Circuit Board (PCB) assembly is a core process in electronics manufacturing that demands meticulous attention to detail. The key to success lies in combining advanced automation with a controlled production environment:

Automated Assembly Lines: Precision automated systems ensure that each component is accurately placed, reducing human error and enhancing overall consistency.

Quality Control (QC): Integrated inspection systems continuously monitor production, detecting any deviations early to keep each PCB within strict specifications

Clean Room Environment: A controlled, contaminant-free space is vital for protecting sensitive components and ensuring long-term product reliability

Semiconductors Manufacturing

Semiconductors manufacturing involves complex, delicate processes that require advanced technologies to achieve optimum yield and performance. Key highlights include:

Advanced Lithography: Utilizing cutting-edge lithography techniques to accurately pattern semiconductor circuits, ensuring the integrity of the design.

Automated Handling: Robotics manage delicate materials with precision, minimizing the risk of damage and ensuring consistent handling throughout the production process.

Yield Optimization: Continuous monitoring and fine-tuning of production parameters help maximize process efficiency, resulting in higher output and improved product performance.

Achieve Excellence in Electronics Production

Meeting the rigorous demands of the electronics industry requires more than just advanced machinery—it requires a commitment to quality at every level. From PCB assembly to semiconductor manufacturing, every process must be optimized for precision and cleanliness. With EnMac’s cutting-edge robotics solutions, manufacturers can not only achieve these goals but also enjoy improved productivity and operational efficiency.

If you are ready to elevate your manufacturing processes and ensure quality in every detail, it’s time to take the next step.

Contact IGNOMAGINE today to learn how our advanced robotics solutions can help you set a new standard in the electronics industry. Let’s work together to bring unmatched precision and quality to every product you create.